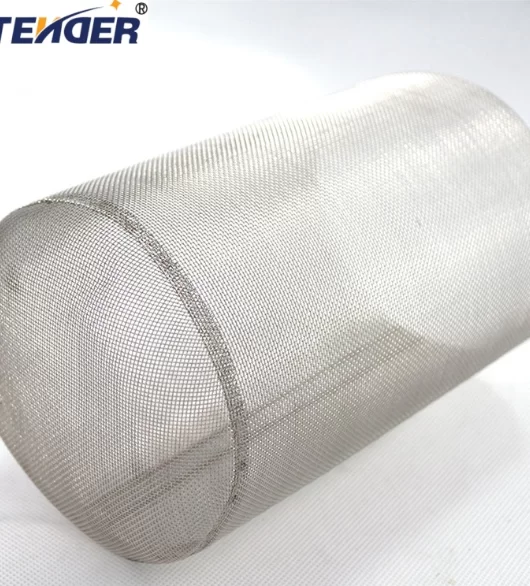

In diverse industrial landscapes, from petrochemical complexes to pharmaceutical manufacturing, efficient and reliable filtration is not merely a component but a critical determinant of operational integrity and product quality. The demand for advanced filtration solutions is consistently rising, driven by stricter environmental regulations, the need for higher purity end-products, and the imperative of protecting sophisticated downstream equipment. This context underscores the vital importance of high-performance filtration media such as the Woven Wire Mesh Filter Tube and Filter Cartridge. These robust cylindrical filter elements, precisely engineered from stainless steel woven metal wire mesh through processes like rolling, welding, or edging, offer a simple yet highly effective solution. Their strong permeability and structural integrity make them indispensable for primary filtration, safeguarding sensitive equipment and pipeline systems from particulate impurities in both liquid and gas streams. Industries ranging from petroleum, chemical, and pharmaceutical to water treatment, food, and machinery widely leverage these filtration capabilities to maintain operational excellence.

The versatility of metal mesh filters, encompassing options like `brass mesh filter`, `filter steel mesh`, `galvanised mesh filters`, and `inline stainless steel mesh filter`, allows for tailored solutions across a spectrum of applications. Each material brings distinct advantages in terms of corrosion resistance, temperature tolerance, and mechanical strength, enabling engineers to select the optimal `filtering mesh` for specific operational challenges. Understanding the technical nuances, manufacturing precision, and application benefits of these filters is paramount for B2B decision-makers seeking to enhance system reliability and reduce maintenance overheads.

Decoding Filter Metal Mesh: Materials, Properties, and Applications

The performance of any filtration system critically hinges on the choice of `filter metal mesh` material. Different metals offer distinct advantages, making them suitable for specific operational environments. For instance, a `brass mesh filter` is highly valued for its excellent electrical conductivity, good thermal conductivity, and resistance to non-oxidizing acids and alkalis, often finding use in marine applications, fuel lines, and some laboratory settings where non-sparking properties are beneficial. Conversely, `filter steel mesh`, particularly stainless steel, is the industry workhorse due to its superior corrosion resistance, high tensile strength, and wide temperature tolerance. This makes `filter steel mesh` ideal for aggressive chemical environments, high-temperature processes, and applications requiring stringent hygiene, such as in the food and pharmaceutical sectors.

For less demanding, yet still crucial applications, `galvanised mesh filters` provide a cost-effective solution. The galvanization process, which involves coating steel with a protective layer of zinc, significantly enhances the mesh's resistance to rust and corrosion in atmospheric conditions. These filters are frequently employed in general industrial filtration, air intake systems, and coarse particle separation. When precision and long-term reliability are paramount, especially in critical fluid systems, `inline stainless steel mesh filter` solutions are often specified. These are engineered for direct integration into pipelines, providing robust and continuous filtration with minimal disruption to flow. Selecting the correct material for your `filtering mesh` is a critical engineering decision that impacts lifespan, efficiency, and overall system cost.

Comparison of Common Metal Mesh Filter Types

Filter Type | Primary Material | Corrosion Resistance | Temperature Range (Approx.) | Key Advantages | Typical Applications |

Brass Mesh Filter | Copper & Zinc Alloy | Good for non-oxidizing acids, alkalis, saltwater | Up to 200°C (392°F) | Non-sparking, conductive, aesthetically pleasing | Marine, fuel filters, decorative, EMI shielding |

Filter Steel Mesh (Stainless Steel) | Stainless Steel (e.g., 304, 316L) | Excellent, esp. 316L for chlorides | Up to 500°C (932°F) + | High strength, wide chemical resistance, hygienic | Petrochemical, food & beverage, pharmaceutical, water treatment |

Galvanised Mesh Filters | Zinc-Coated Steel | Good for atmospheric corrosion | Up to 200°C (392°F) | Cost-effective, good rust protection | General industrial, air filtration, less aggressive environments |

Fig 1: Illustrative example of custom metal mesh filters being inspected during manufacturing.

The Art and Science of Manufacturing Filter Mesh

The production of high-quality `filtering mesh` components, especially for `custom metal mesh filters`, is a meticulous process demanding precision at every stage. It typically begins with the selection of premium-grade raw materials, whether it's stainless steel, brass, or galvanized wire, ensuring compliance with international standards like ASTM and DIN. The core manufacturing process involves weaving the metal wires into a mesh pattern, which defines the filtration efficiency and mechanical properties. This weaving can be plain weave, twill weave, or Dutch weave, each offering distinct characteristics in terms of pore size, open area, and strength. Following weaving, the mesh undergoes a series of precision forming operations to create the final filter element, such as a Woven Wire Mesh Filter Tube or Cartridge.

Key manufacturing steps include:

· Weaving: High-precision looms create mesh with consistent pore sizes.

· Rolling/Forming: The woven mesh is then rolled into cylindrical shapes.

· Welding: Seam welding (e.g., TIG, laser welding) is applied to ensure structural integrity and prevent bypass, crucial for `filter steel mesh` and `inline stainless steel mesh filter`.

· Edging/Finishing: Edges are typically reinforced or capped using various materials and methods to enhance durability and prevent unraveling.

· Cleaning & Surface Treatment: Filters are thoroughly cleaned to remove contaminants and may undergo passivation for enhanced corrosion resistance, particularly for stainless steel.

Throughout these stages, rigorous quality control is maintained, adhering to international inspection standards such as ISO 9001 for quality management and specific material standards (e.g., ANSI B31.3 for process piping). Performance testing includes pore size distribution analysis, flow rate measurement, and pressure drop evaluation. This stringent approach ensures that products like `fine mesh filter` elements deliver consistent performance, offering superior energy efficiency by minimizing pressure loss and excellent corrosion resistance, leading to an extended service life in demanding environments like petrochemical and metallurgical plants.

Technical Specifications of Woven Wire Mesh Filter Cartridges

The effectiveness of a Woven Wire Mesh Filter Tube or Filter Cartridge is defined by a range of critical technical parameters. These include the nominal or absolute filtration rating, which specifies the minimum particle size retained; the design flow rate, indicating the volume of fluid processed per unit time; and the initial pressure drop, a measure of resistance to flow. Other vital specifications encompass material composition (e.g., SS304, SS316L for `filter steel mesh`), operating temperature and pressure limits, and physical dimensions such as diameter and length. For applications requiring exceptionally clean output, a `fine mesh filter` is designed with very small pore sizes, often measured in microns, to capture sub-micron particles effectively. Engineers must carefully consider these specifications to ensure compatibility with system requirements and to optimize filtration performance and operational costs.

Below is a table illustrating typical specifications for Woven Wire Mesh Filter Tubes, emphasizing the ranges available for `custom metal mesh filters` to meet specific industrial needs.

Typical Specifications for Woven Wire Mesh Filter Tubes/Cartridges

Parameter | Range/Description |

Filtration Rating | 5 microns to 2000 microns (Absolute or Nominal) |

Material | SS304, SS316, SS316L, Brass, Galvanized Steel, Monel, Hastelloy |

Operating Temperature | -200°C to +500°C (-328°F to +932°F) depending on material |

Max. Operating Pressure | Up to 50 bar (725 psi) or higher for reinforced designs |

Standard Diameter Range | 25 mm to 200 mm (1 inch to 8 inches) |

Standard Length Range | 100 mm to 1000 mm (4 inches to 40 inches) |

End Cap Configurations | DOE, SOE, threaded, flange, custom designs |

Woven Wire Mesh Filter Cartridge Application Distribution (Conceptual Pie Chart Data)

To further illustrate the widespread utility of these filters, consider a conceptual pie chart demonstrating typical application distribution by industry. Based on aggregated industry data, the primary sectors leveraging Woven Wire Mesh Filter Cartridges include:

· Petrochemical & Oil & Gas: 30% (e.g., pre-filtration, process fluid filtration, fuel filtration)

· Water Treatment: 25% (e.g., wastewater, potable water, desalination pre-treatment, especially with `galvanised mesh filters`)

· Food & Beverage: 15% (e.g., clarification, syrup filtration, process water filtration, requiring `filter steel mesh` hygiene)

· Pharmaceutical & Biotech: 10% (e.g., buffer filtration, solvent recovery, utilizing `fine mesh filter` precision)

· Machinery & Hydraulics: 10% (e.g., lubrication oil filtration, hydraulic fluid cleaning, often with `brass mesh filter` or stainless steel)

· Other Industrial Processes: 10% (e.g., pulp & paper, mining, power generation)

This distribution highlights the filter's adaptability and critical role in diverse industrial processes, emphasizing its market penetration and versatility as a core `filtering mesh` technology.

Advanced Filtering Solutions: Fine Mesh and Inline Filters

For specialized applications demanding superior particle removal, the `fine mesh filter` plays a pivotal role. These filters are engineered with exceptionally small aperture sizes, often down to a few microns, utilizing advanced weaving techniques. This capability is critical in industries such as pharmaceuticals, where preventing particulate contamination is crucial for product efficacy and safety, and in high-purity chemical manufacturing, where even trace impurities can compromise reactions or final product specifications. The meticulous design of `fine mesh filter` elements ensures a high surface area for filtration, translating into longer service life and reduced frequency of change-outs, thereby enhancing energy efficiency by maintaining optimal flow dynamics and minimizing pressure differentials over extended periods.

Furthermore, the `inline stainless steel mesh filter` is a cornerstone in process protection, designed for seamless integration directly into pipeline systems. Its robust construction from `filter steel mesh` (typically SS304 or SS316L) ensures exceptional corrosion resistance, making it suitable for aggressive media and high-temperature environments. Inline filters act as a first line of defense, protecting pumps, valves, heat exchangers, and sensitive instrumentation from damage caused by debris and particulate matter. This proactive approach significantly reduces maintenance costs, extends equipment lifespan, and prevents costly downtime, providing substantial long-term operational savings. Both `fine mesh filter` and `inline stainless steel mesh filter` solutions embody precision engineering for critical industrial applications.

Fig 2: Example of a fine mesh filter integrated into an inline system for critical liquid filtration.

Customization and Engineering Expertise in Metal Mesh Filters

While standard filter elements suffice for many applications, the complexity of modern industrial processes frequently necessitates `custom metal mesh filters`. Specialized requirements, such as unique flow rates, specific particle size removal, non-standard dimensions, or extreme operating conditions (high temperature, corrosive media), call for bespoke engineering solutions. A reputable manufacturer offers comprehensive customization programs, working closely with clients from initial design conceptualization through material selection, prototyping, and final production. This collaborative approach ensures that the `custom metal mesh filters` precisely meet the operational demands and performance criteria, whether it's a specialized `brass mesh filter` for chemical compatibility or an intricately designed `filter steel mesh` for high-pressure systems.

When evaluating manufacturers for `custom metal mesh filters`, B2B decision-makers should prioritize several key criteria:

· Engineering Expertise: A team with extensive knowledge in material science, fluid dynamics, and filtration technology.

· Manufacturing Capabilities: Advanced equipment for weaving, welding, and forming diverse mesh configurations, including `fine mesh filter` and `galvanised mesh filters`.

· Quality Certifications: Adherence to international standards like ISO 9001, and material-specific certifications.

· Prototyping & Testing: Ability to develop and rigorously test prototypes to validate performance before full-scale production.

· Lead Times & Scalability: Responsive production schedules and the capacity to scale up for larger orders without compromising quality.

By partnering with an experienced and capable supplier, companies can leverage specialized expertise to develop optimal `filtering mesh` solutions that deliver unparalleled efficiency and reliability.

Application Case Studies & Industry Impact of Filtering Mesh

The practical application of `filtering mesh` technology is best illustrated through real-world case studies demonstrating its profound industry impact. In the petrochemical sector, for example, `inline stainless steel mesh filter` cartridges are routinely deployed upstream of critical compressors and turbines to prevent damage from pipe scale and welding slag, significantly extending equipment service intervals and avoiding costly unplanned shutdowns. One notable instance involved a refinery using custom `filter steel mesh` elements to purify crude oil feedstocks, resulting in a 15% reduction in catalyst fouling and a substantial increase in processing throughput.

In the water treatment industry, particularly for municipal potable water systems, `galvanised mesh filters` and stainless steel mesh filters are critical for removing suspended solids, protecting sensitive reverse osmosis membranes, and ensuring compliance with stringent water quality standards. A major desalination plant successfully implemented a series of large-diameter `custom metal mesh filters` for pre-filtration, reducing turbidity by over 90% and extending the lifespan of downstream membrane filters by two years, a testament to the durability and efficiency of woven mesh solutions. Similarly, in the food and beverage industry, `fine mesh filter` elements made from hygienic `filter steel mesh` are indispensable for clarifying juices, filtering edible oils, and ensuring product consistency, often meeting FDA compliance for direct food contact. These diverse examples underscore the versatility and essential contribution of robust `filtering mesh` solutions across varied industrial landscapes.

Fig 3: An industrial application showcasing the installation of filtering mesh in a large-scale system.

Ensuring Trust and Reliability: Our Commitment to Quality and Service

Establishing and maintaining trust is fundamental in the B2B filtration sector. Our commitment to excellence is underpinned by rigorous adherence to international quality standards, including ISO 9001:2015 certification, ensuring consistent product quality from material sourcing to final dispatch for all our `brass mesh filter`, `filter steel mesh`, and `galvanised mesh filters`. For applications in sensitive industries like food and pharmaceuticals, our `fine mesh filter` products are manufactured in compliance with FDA guidelines, where applicable, providing an additional layer of assurance regarding safety and suitability. We also partner with leading industry bodies and leverage third-party testing to validate the performance data of our Woven Wire Mesh Filter Tubes and Filter Cartridges, providing transparent and verifiable metrics on filtration efficiency, pressure drop, and service life.

Beyond product quality, we prioritize comprehensive customer support and reliable logistics. Our standard lead times for common `inline stainless steel mesh filter` and `filter metal mesh` products are typically 2-4 weeks, with expedited options available for urgent requirements. For `custom metal mesh filters`, project-specific timelines are established in close consultation with the client to meet precise operational windows. All our products are backed by a robust warranty, covering manufacturing defects and ensuring that our `filtering mesh` solutions perform as specified. Our dedicated technical support team is available to assist with product selection, installation guidance, and troubleshooting, ensuring seamless integration and optimal performance throughout the product lifecycle. This holistic approach guarantees not just a product, but a complete filtration solution built on trust and reliability.

Frequently Asked Questions (FAQ) about Metal Mesh Filters

Q1: What are the primary advantages of a Woven Wire Mesh Filter Tube over other filter media?

A1: Woven wire mesh filters offer superior mechanical strength, high temperature and pressure resistance, excellent chemical compatibility, and are often cleanable and reusable, leading to lower operating costs and a longer service life compared to disposable cartridge filters. They maintain a precise and stable pore structure for consistent filtration performance.

Q2: How do I select the correct material for my `filter metal mesh`?

A2: Material selection depends on several factors: the corrosiveness of the fluid, operating temperature and pressure, mechanical stress, and desired lifespan. Stainless steels (304, 316L) are common for broad resistance, `brass mesh filter` for non-sparking needs, and `galvanised mesh filters` for economical atmospheric corrosion resistance. Consult our technical team for specific recommendations.

Q3: What is the significance of the "filtration rating" for a `fine mesh filter`?

A3: The filtration rating indicates the smallest particle size that the filter can effectively capture. For a `fine mesh filter`, this is usually expressed in microns (µm). An "absolute" rating specifies that a certain percentage (e.g., 99.9%) of particles above that size are removed, while a "nominal" rating is less precise, representing an average pore size or typical removal efficiency.

Q4: Can `custom metal mesh filters` be manufactured to specific dimensions or end connections?

A4: Absolutely. Customization is a key strength of woven wire mesh filters. We offer bespoke manufacturing for `custom metal mesh filters` to match precise dimensions, flow rates, end cap configurations (e.g., Double Open End, Single Open End with specific fittings, threaded connections), and specialized material combinations to integrate seamlessly into existing systems.

Q5: What are the typical industries that utilize `inline stainless steel mesh filter` products?

A5: `Inline stainless steel mesh filter` units are widely used across diverse sectors including petrochemical, oil & gas, water treatment, food & beverage, pharmaceutical, and general manufacturing. They serve as crucial protection for pumps, nozzles, heat exchangers, and other sensitive downstream equipment against solid contaminants in pipelines.

Q6: How does the manufacturing process ensure the quality and durability of `filter steel mesh`?

A6: Quality and durability are assured through precision weaving for uniform pore size, robust welding techniques (like TIG or laser welding) for seam integrity, and meticulous edging to prevent fraying. Post-production, filters undergo thorough cleaning and often passivation for stainless steel, followed by rigorous quality checks including visual inspection, dimensional verification, and sometimes flow/pressure drop testing, adhering to ISO standards.

Q7: What is the expected service life for a `filtering mesh` element, and how can it be maximized?

A7: The service life of `filtering mesh` varies significantly based on material, operating conditions, fluid characteristics, and maintenance. Stainless steel filters can last for several years with proper care. To maximize life, ensure correct material selection for the application, adhere to recommended operating parameters (pressure, temperature), implement a regular cleaning regimen (backwashing, ultrasonic cleaning), and replace elements when pressure differential limits are reached.

Conclusion

In conclusion, the strategic deployment of Woven Wire Mesh Filter Tubes and Filter Cartridges, including specialized variants like `brass mesh filter`, `filter steel mesh`, `galvanised mesh filters`, `fine mesh filter`, and `inline stainless steel mesh filter`, is fundamental to achieving operational excellence across a multitude of industries. These robust and versatile `filtering mesh` solutions are indispensable for protecting critical equipment, ensuring product purity, and complying with stringent environmental and quality standards. By understanding the diverse material properties, precise manufacturing processes, and tailored `custom metal mesh filters` available, B2B stakeholders can make informed decisions that lead to enhanced efficiency, extended equipment lifespan, and significant cost savings. Our commitment to quality, technical expertise, and comprehensive customer support ensures that we provide not just filtration products, but reliable, long-term solutions that drive industrial success.

References

1. ISO 9001:2015 Quality Management Systems – Requirements. International Organization for Standardization.

2. ASTM International Standards on Metal Mesh and Wire Cloth for Testing Purposes.

3. Perry's Chemical Engineers' Handbook, 9th Edition. McGraw-Hill Education.

4. U.S. Food and Drug Administration (FDA) Regulations for Materials in Contact with Food.

5. "Filtration and Separation Principles and Practices" by M.J. Matteson and C. Orr. CRC Press.

連絡先

Product

Copyright © 2025 Anping Tengde Metal Wire Mesh Products Co.、Ltd。All Rights Reserved. Sitemap | Privacy Policy

Please leave us a message and we will get back to you shortly.

If you are interested in our products, you can choose to leave your information here, and we will be in touch with you shortly.